In the Tongue & Groove Flange Asme B16.5 Class 300, both the Tongue face as well as the Groove faces must be matched to each other. One of the flange faces has been produced with a raised ring also referred to as Tongue, machined onto the flange face by the Stainless Steel Tongue & Groove Flange Manufacturers India. Similarly, the mating flange has a matching depression also known as a Groove that has been machined into its face by the Tongue and Groove Flange Manufacturers in India. Fitwel Industries LLP is a leading independent Carbon Steel Tongue and Groove Flange manufacturer in India. We have extensive experience in supplying Carbon Steel Tongue & Groove Flange are stocked or available in the following range of sizes and materials for the petrochemical, oil, gas, and allied industries. Tongue & Groove Flange can be assembled and disassembled easily with Pipes. SS Tongue & Groove Flange can be forged or plate. Fitwel Industries LLP is a well known Alloy Steel Tongue & Groove Flange manufacturer in India, we offer these Copper Tongue & Groove Flange, Copper Nickel Tongue & Groove Flange, Brass Tongue & Groove Flange, Hastelloy Tongue & Groove Flange, Inconel Tongue & Groove Flange, Monel Tongue & Groove Flange, Alloy 20 Tongue & Groove Flange, Aluminium Tongue & Groove Flange, Nickel Tongue & Groove Flange, Duplex Tongue & Groove Flange, Super Duplex Tongue & Groove Flange, Incoloy Tongue & Groove Flange, 254 Smo Tongue & Groove Flange and Titanium Tongue & Groove Flange in all standard in which the common world standards include ASA/ ANSI/ ASME (USA), BS10 (British/ Australian), PN/ DIN (European) and JIS/ KS (Japanese/ Korean). Many Alloy Steel Tongue & Groove Flange manufacturers in India produce these Carbon Steel Tongue & Groove flanges from forged materials and have machined surfaces. Compare our price from Tongue & Groove Flange manufacturers in India or China you will find the best rate from our company.

Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. ASME B16.5 and B16.47 define various types of flange facings, including the raised face, the large male and female facings which have identical dimensions to provide a relatively large contact area.

Other flange facings covered by these standards include the large and small tongue-and-groove facings, and the ring joint facing specifically for ring joint type metal gaskets.

The Raised Face flange is the most common type used in process plant applications, and is easily to identify. It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face. This face type allows the use of a wide combination of gasket designs, including flat ring sheet types and metallic composites such as spiral wound and double jacketed types.

The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint. Diameter and height are in ASME B16.5 defined, by pressure class and diameter. Pressure rating of the flange determines the height of the raised face.

The typical flange face finish for ASME B16.5 RF flanges is 125 to 250 µin Ra (3 to 6 µm Ra).

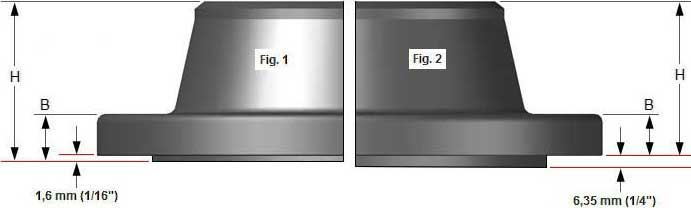

For the height measures H and B of all described dimensions of flanges on this website, with exception of the Lap Joint flange, it is important to understand and remember the following:

In pressure classes 150 and 300, the height of raised face is approximately 1.6 mm (1/16 inch). In these two pressure classes, almost all suppliers of flanges, show in their catalog or brochure, the H and B dimensions including the raised face height. ((Fig. 1))

In pressure classes 400, 600, 900, 1500 and 2500, the height of raised face is approximately 6.4 mm (1/4 inch). In these pressure classes, most suppliers show the H and B dimensions excluding the raised face height. (Fig. 2)

The Flat Face flange has a gasket surface in the same plane as the bolting circle face. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting.

Flat face flanges are never to be bolted to a raised face flange. ASME B31.1 says that when connecting flat face cast iron flanges to carbon steel flanges, the raised face on the carbon steel flange must be removed, and that a full face gasket is required. This is to keep the thin, bittle cast iron flange from being sprung into the gap caused by the raised face of the carbon steel flange.

The Ring Type Joint flanges are typically used in high pressure (Class 600 and higher rating) and/or high temperature services above 800°F (427°C). They have grooves cut into their faces which steel ring gaskets. The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or Coining) the gasket to make intimate contact inside the grooves, creating a metal to metal seal.

An RTJ flange may have a raised face with a ring groove machined into it. This raised face does not serve as any part of the sealing means. For RTJ flanges that seal with ring gaskets, the raised faces of the connected and tightened flanges may contact each other. In this case the compressed gasket will not bear additional load beyond the bolt tension, vibration and movement cannot further crush the gasket and lessen the connecting tension.

Ring Type Joint gaskets are metallic sealing rings, suitable for high-pressure and high-temperature applications. They are always applied to special, accompanying flanges which ensure good, reliable sealing with the correct choice of profiles and material.

Ring Type Joint gaskets are designed to seal by "initial line contact" or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the "softer" metal of the gasket flows into the microfine structure of the harder flange material, and creating a very tight and efficient seal.

Most applied type is style R ring that is manufactured in accordance with ASME B16.20 used with ASME B16.5 flanges, class 150 to 2500. Style 'R' ring type joints are manufactured in both oval and octagonal configurations.

The Octagonal ring has a higher sealing efficiency than the oval and would be the preferred gasket. However, only the oval cross section can be used in the old type round bottom groove. The newer flat bottom groove design will accept either the oval or the octagonal cross section.

Style R ring type joints are designed to seal pressure up to 6,250 psi in accordance with ASME B16.5 pressure ratings and up to 5,000 psi.

The RX type is suitable for pressures up to 700 bar. This RTJ is capable of sealing itself. The outer sealing surfaces make the first contact with the flanges. A higher system pressure causes a higher surface pressure. Type RX is interchangeable with the standard R-models.

The BX type is suitable for very high pressures up to 1500 bar. This ring joint is not interchangeable with other types, and is only suited for API type BX flanges and grooves.

The sealing surfaces on the ring joint grooves must be smoothly finished to 63 Microinches and be free of objectionable ridges, tool or chatter marks. They seal by an initial line contact or a wedging action as the compressive forces are applied. The hardness of the ring should always be less than the hardness of the flanges.

The table below indicates the most commonly used materials for ring type joints.

The Tongue and Groove faces of this flanges must be matched. One flange face has a raised ring (Tongue) machined onto the flange face while the mating flange has a matching depression (Groove) machined into it's face.

Tongue-and-groove facings are standardized in both large and small types. They differ from male-and-female in that the inside diameters of the tongue-and-groove do not extend into the flange base, thus retaining the gasket on its inner and outer diameter. These are commonly found on pump covers and Valve Bonnets.

Tongue-and-groove joints also have an advantage in that they are self-aligning and act as a reservoir for the adhesive. The scarf joint keeps the axis of loading in line with the joint and does not require a major machining operation.

General flange faces such as the RTJ, TandG and the FandM shall never be bolted together. The reason for this is that the contact surfaces do not match and there is no gasket that has one type on one side and another type on the other side.

With this type the flanges also must be matched. One flange face has an area that extends beyond the normal flange face (Male). The other flange or mating flange has a matching depression (Female) machined into it's face.

The female face is 3/16-inch deep, the male face is1/4-inch high, and both are smooth finished. The outer diameter of the female face acts to locate and retain the gasket. In principle 2 versions are available; the Small M&F Flanges and the Large M&F Flanges. Custom male and female facings are commonly found on the Heat Exchanger shell to channel and cover flanges.

Better sealing properties, more precise location and exact compression af sealing material, utilization of other, more suitable sealing and spezialized sealing material (O-rings).

Commercial availabillity and cost. Normal raised faced is far more common and ready available both regarding Valves, flanges and sealing material. Another complexity is that some rigid rules must be applied to the piping design. Do you order Valves to be female end both sides, or on one side maybe, in which case do you point all male ends in the flow direction, or what. Same applies to any flanged joint / vessel connection of course.

Standard : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2" (15 NB) to 48" (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

BS : BS4504 , BS4504, BS1560, BS10

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

Stainless Steel Tongue and Groove Flanges : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

Duplex & Super Duplex Steel Tongue and Groove Flanges : ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61, 2205 (UNS No. S31803), 2507 (UNS No. S32750)

Carbon Steel Tongue and Groove Flanges : ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70, ASTM A350, LF2, LF3

Alloy Steel Tongue and Groove Flanges : ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Nickel Alloy Tongue and Groove Flanges :ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020).

Copper Alloy Steel Tongue and Groove Flanges : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

| Tongue and Groove Flanges Manufacturer in India | Tongue and Groove Flanges Manufacturer |

| ASME B16.9 Tongue and Groove Flanges | Stainless Steel Orifice Plate Plate Flanges |

| Forged Tongue and Groove Flanges Suppliers | Stainless Steel Orifice Plate Plate Flanges |

| ANSI B16.9 Tongue and Groove Flanges Dealer | ASME B16.28 Tongue and Groove Flanges Exporter |

| Carbon Steel Tongue and Groove Flanges | High Quality Tongue and Groove Flanges Manufacturer |

| ASTM A403 Alloy Steel Tongue and Groove Flanges | Duplex Steel Tongue and Groove Flanges |

| Super Duplex Steel Tongue and Groove Flanges | Copper Nickel Tongue and Groove Flanges |

| High Nickel Alloy Tongue and Groove Flanges | Hastelloy Tongue and Groove Flanges |

| Titanium Tongue and Groove Flanges | Inconel Tongue and Groove Flanges |

ASME B16.9 Tongue and Groove Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Tongue and Groove Flanges through a worldwide network of stock-keeping branches. These Plate & Forged Flanges is used in various industries like:

We are renowned & most acclaimed Manufacturers, Suppliers & Exporter And Stockist of Tongue and Groove Flanges in Stainless Steel.

For More Information About, Tongue and Groove Please Call 91-22-2382 9256 or Send an Email to sales@fitwelindia.com